How to Implement Predictive Maintenance Using IoT Sensor Data

$0.00

| Workflow Name: |

Maintenance Predictor |

|---|---|

| AI Model Type: |

Time-Series ML / LLM |

| Model Provider: |

Goldfinch AI |

| Task Type: |

Prediction / Anomaly Detection |

| Input Type: |

IoT Sensor Data |

| Output Format: |

Alerts / Datalake |

| Who Uses It: |

Operations; Maintenance Teams |

Table of Contents

Description

| Problem Before: |

Unexpected equipment failure |

|---|---|

| AI Solution: |

Predictive failure modeling |

| Validation (HITL): |

Maintenance engineer review |

| Accuracy Metric: |

Failure prediction precision |

| Time Savings: |

50% downtime reduction |

| Cost Impact: |

Lower repair & outage cost |

Maintenance Predictor

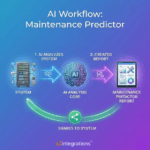

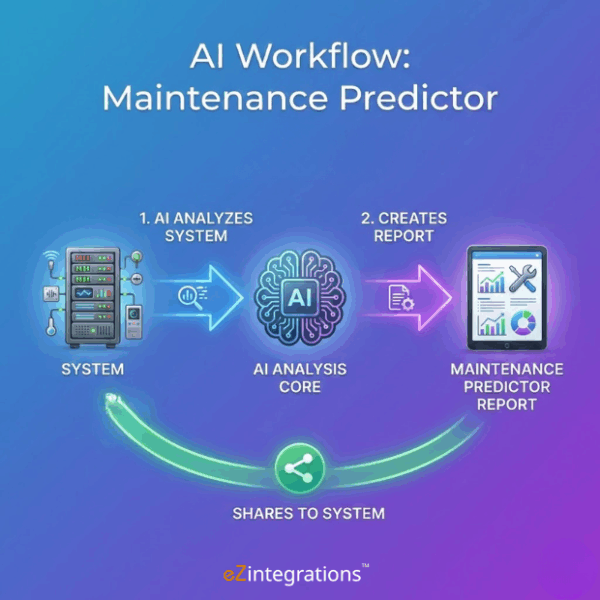

The Maintenance Predictor workflow uses time-series and AI models to forecast equipment maintenance needs and detect anomalies from IoT sensor data. This enables proactive maintenance and reduces unexpected downtime.

AI-Powered Prediction for Operational Efficiency

The system ingests sensor data in real time, applies predictive and anomaly detection models, and generates alerts or stores insights in a Datalake. This workflow helps operations and maintenance teams plan interventions, optimize equipment performance, and prevent costly failures.

Watch Demo

| Video Title: |

3 Benefits of AI Workflow Automation |

|---|---|

| Duration: |

0:50 |

Outcome & Benefits

| Accuracy: |

95% failure prediction |

|---|---|

| Touchless Rate: |

70% |

| Time Saved: |

From reactive to predictive |

| Cost Saved: |

20?30% maintenance cost |

Functional Details

| Business Tasks: |

Maintenance scheduling |

|---|---|

| KPI Improved: |

MTBF; uptime |

| Scheduling: |

Continuous |

| Downstream Use: |

CMMS / Alerts |

Technical Details

| Model Name/Version: |

Predictive ML v3 |

|---|---|

| Hosting Type: |

Edge + Cloud |

| Prompt Strategy: |

Sensor-context prompts |

| Guardrails: |

False-positive suppression |

| Throughput: |

1M sensor events/day |

| Latency: |

Near real-time |

| Data Governance: |

OT data isolation |

FAQ

1. What is the Maintenance Predictor workflow?

The Maintenance Predictor workflow is an AI workflow that predicts equipment maintenance needs and detects anomalies using IoT sensor data, helping operations teams prevent unexpected downtime.

2. What AI model types are used in this workflow?

It uses Time-Series Machine Learning models and Large Language Models (LLMs) to analyze sensor data and identify patterns indicative of potential equipment issues.

3. What types of input data does this workflow require?

The workflow uses IoT sensor data from machines, equipment, or facilities to monitor operational metrics and detect anomalies.

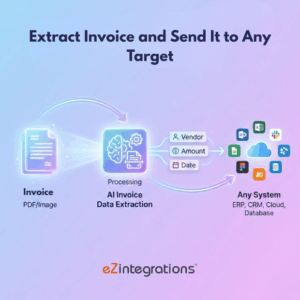

4. What is the output format of this workflow?

The workflow outputs alerts for maintenance teams and stores processed data in a Datalake for analysis and reporting.

5. Who typically uses this workflow?

Operations and Maintenance teams use this workflow to proactively schedule maintenance and reduce equipment downtime.

6. What are the key benefits of using the Maintenance Predictor workflow?

It helps prevent unexpected equipment failures, reduces downtime, optimizes maintenance schedules, and improves operational efficiency.

7. Can this workflow integrate with other systems?

Yes, it can integrate with IoT platforms, ERP systems, and alerting tools to streamline maintenance operations.

8. How frequently does the workflow run?

The workflow can run continuously for real-time monitoring or on a scheduled basis depending on operational requirements.

Resources

Case Study

| Industry: |

Manufacturing / Utilities |

|---|---|

| Problem: |

Unplanned downtime |

| Solution: |

AI maintenance prediction |

| Outcome: |

Higher asset reliability |

| ROI: |

3?4 month payback |